DemoUpBlog

#6 - Why flow is key for successful carbon mineralization

April 2024 - Eleni Stavropoulou

Carbon mineralization in Basalts is an efficient technology for permanent CO2 storage through mineral reaction between the hosting rock and the injected CO2. But what do we know about the interplay between mineralization and pore clogging and how can it impact storage capacity? Results from lab testing and pore network modelling have revealed the role of micro-porosity in controlling these phenomena.

#5 - Testing a new procedure: first injection of CO2 dissolved in seawater into basalts in Iceland

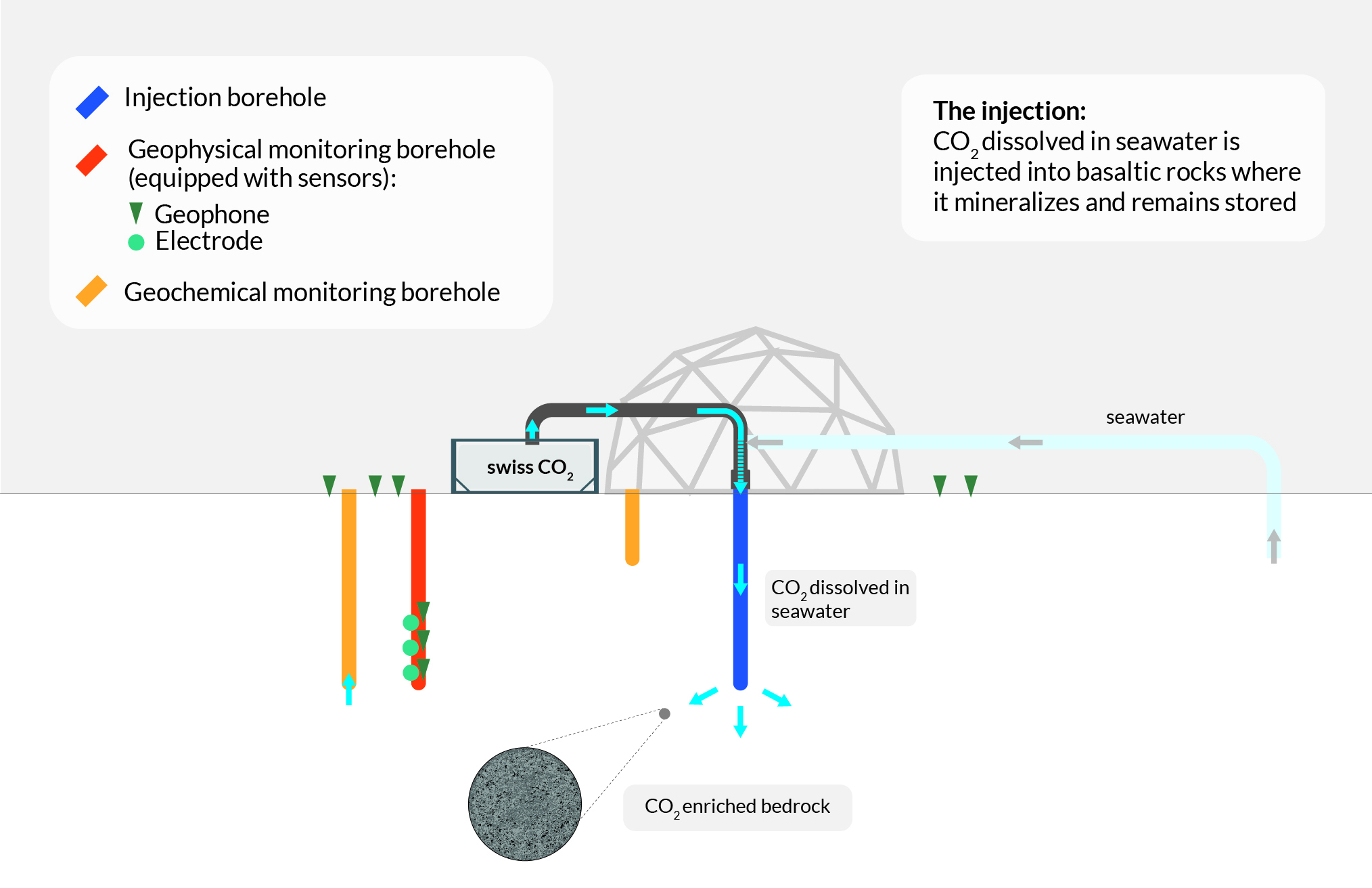

November 2023 - Alba Zappone, Stefan Wiemer, Anne Obermann

At the beginning of November, the first injection of CO2 transported from Switzerland mixed with seawater in the Icelandic underground was started. The injection is monitored with a detailed geophysical and geochemical monitoring network, designed to track fluid propagation and CO2 mineralization processes. The DemoUpCARMA and DemoUpStorage partner projects in collaboration with Carbfix will continue transporting and injecting CO2 until autumn 2024.

#4 - Life-Cycle Impact Assessment of Carbonated Recycled Concrete Aggregate: A Sustainable Pathway

September 2023 - Romain Sacchi, Andreas Leeman, Christian Bauer

In the first blog post (see post #1), Johannes Tiefenthaler gave us some insights on the carbonated Recycled Concrete Aggregate (RCA) supply chain operated by Neustark. In a second blog post (see post #2), the dedicated research team of Andreas Leemann and Frank Winnefeld at Empa described the microstructural change in concrete when using RCA. This post will delve deeper into the environmental life-cycle impact assessment (LCA) of accelerated CO2 mineralization in RCA as it is executed by Neustark. This blog post aims to provide a comprehensive understanding of the system boundaries and, most importantly, reveal the potential for 1) removing CO2 from the atmosphere via accelerated CO2 mineralization, and 2) reducing greenhouse gas (GHG) emissions via reduced virgin material sourcing.

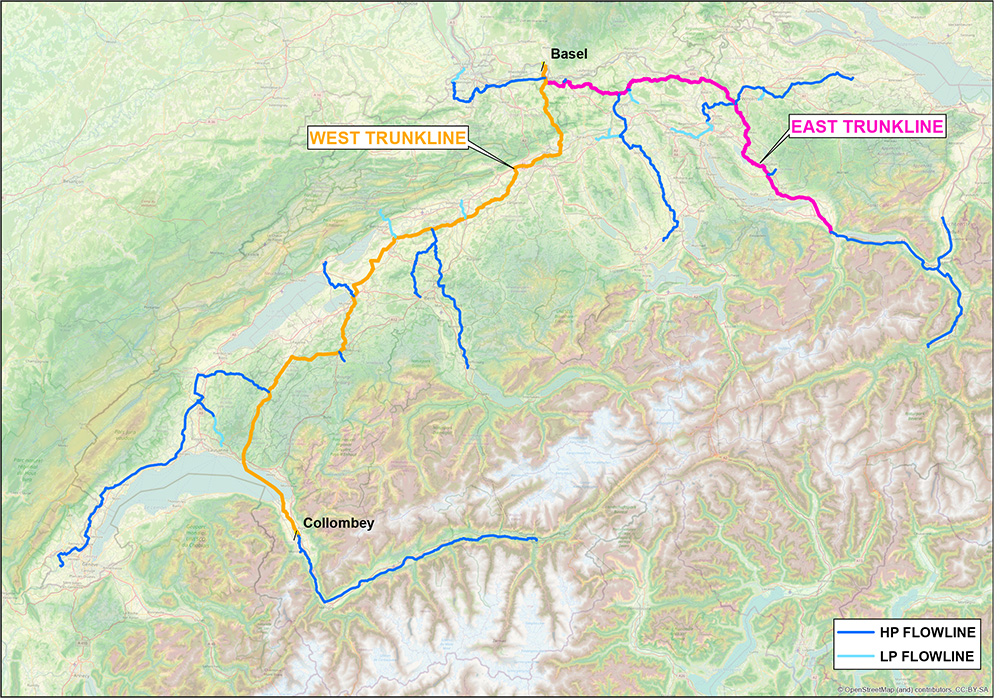

#3 - How a CO2 pipeline network in Switzerland could be governed and financed

July 2023 - Oliver Akeret & Martynas Bagdonas, Sustainability in Business Lab at ETH Zurich

In August 2022, for the first time ever, CO2 captured from a waste-water treatment plant in Switzerland was transported to Iceland for injection and mineralization in geological formations underground in the context of the pilot project DemoUpCARMA.

The choice of Iceland as a storage site, which significantly extends the length of the transport route, is no coincidence. Research projects have shown limited potential for storing CO2 in geological storage formations in the near future in Switzerland. Therefore, exploring alternative storage options is critical. After capturing the CO2 at ARA Bern, the CO2 is liquefied and loaded onto portable ISO containers with a capacity of 20 tons, which can keep the CO2 in a liquid state until arrival at the storage site. The ISO containers are transported via truck from ARA Bern to the train station in Weil am Rhein. From there, the CO2 is transported first via rail to Rotterdam and then via ship to Reykjavik. Once delivered in Reykjavik, the ISO container is transferred to the injection site via truck.

#2 - Investigating concrete mix design with carbonated RCA

June 2023 - by Andreas Leemann, Frank Winnefeld, Johannes Tiefenthaler

The previous blog post "How we can lower the carbon footprint of concrete today" gives an insight into the carbonation process of recycled concrete in order to remove CO2 from the atmosphere and generate negative emissions. In this new blog post, we’d like to highlight the microstructural changes occurring in recycled concrete aggregates (RCA) as a result of accelerated carbonation. These changes have significant implications for concrete production. Laboratory analyses not only show an increased compressive strength but also the potential to reduce the cement content in recycling concrete – which offers in terms of lowering the carbon footprint. Understanding these microstructural transformations becomes paramount in paving the way for the commercialization of carbonated concrete.

#1 - How we can lower the carbon footprint of concrete today

December 2022 - by Johannes Tiefenthaler

With over 1 billion tons per year, concrete from construction and demolition is the world's single largest waste stream. ETH spin-off Neustark developed a method to help turn this waste stream into a carbon sink, thus permanently removing CO2 from the atmosphere and generating negative emissions. To achieve that, a solution was conceived that mineralizes CO2 and stores it in recycled concrete aggregate. In 2017, the company started developing this process, and in 2022, they were able to deploy it at industrial scale within the framework of DemoUpCARMA.