#1 Blog

How we can lower the carbon footprint of concrete today

Dezember 2022 - by Johannes Tiefenthaler, Co-Founder and Co-CEO at Neustark

With over 1 billion tons per year, concrete from construction and demolition is the world's single largest waste stream. ETH spin-off Neustark developed a method to help turn this waste stream into a carbon sink, thus permanently removing CO2 from the atmosphere and generating negative emissions. To achieve that, a solution was conceived that mineralizes CO2 and stores it in recycled concrete aggregate. In 2017, the company started developing this process, and in 2022, they were able to deploy it at industrial scale within the framework of DemoUpCARMA.

The recycling streams: working with concrete producers

To investigate the domestic Carbon dioxide Capture, Utilization and Storage (CCUS) pathway, Neustark collaborates with the concrete producer Kästli. Kästli produces two recycled products that can fix CO2, which is of biogenic origin in the DemoUpCARMA project: concrete aggregate and concrete slurry.

Concrete aggregate is produced by crushing demolition concrete – originating from the demolition of concrete structures – for the subsequent re-use in road construction or for the production of new concrete. After crushing, the concrete aggregate is transported via conveyor belts to silos where it is temporarily stored. Concrete slurry is a side product from washing trucks and concrete batching systems. This slurry is typically water with a solid content (mainly cement and sand) of less than 10 % in mass. It is typically collected in a basin and reused as a pure-water replacement for ready mix concrete.

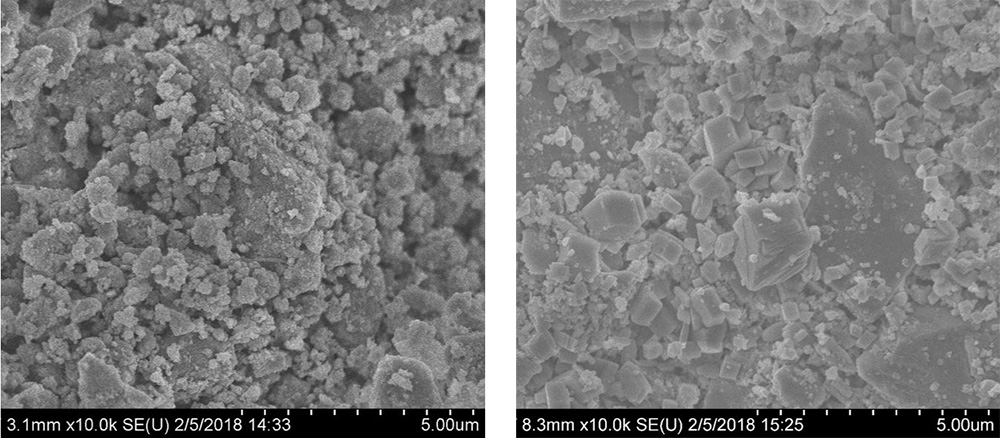

The physics: transforming CO2 into rock

Both concrete aggregate and concrete slurry contain hydrated cement phases. These hydrated cement phases are in contact with water – and thus in a solid-liquid equilibrium. Part of the hydrated cement is dissolved in the water and is present as ionic. As CO2 is also dissolved in this water, a new mineral that exhibits a lower solubility than the hydrated cement phases precipitates, – and voilà, calcium carbonate (CaCO3) is formed. Thus, the CO2 and the hydrated cement undergo a chemical transformation to form rock. This so-called carbonation reaction of 1 kg CO2 releases heat such that the temperature of 1,000 kg of concrete increases by 4 to 5°C.

CaCO3 is considered to be amongst the most permanent ways to sequester carbon. Only temperatures above 600°C or very strong acids could trigger the release of CO2.This ensures that the CO2 remains stored in the concrete, even if it is demolished again after being reused.

Figure 1 – Microscopic view of concrete aggregate before (left) and after (right) injecting CO2: the calcium carbonates are visible as cube shaped crystals.

The technology: making ‘sinking CO2 into concrete’ an integral part of recycling

Neustark’s ambition is to broadly deploy this process and the underlying technology. One of the key success factors to industrial deployment is a seamless integration of the CO2 storage technology within existing concrete producers’ facilities.

This integration process is investigated as part of DemoUpCARMA project: The existing aggregate storage silos at Kästli’s concrete plant have been retrofitted with a CO2 silo in order to integrate Neustark’s procedure directly at the plant. Additionally, a monitoring system has been installed to observe and control the CO2 uptake. Moreover, the concrete slurry carbonation plant was designed as a palette-sized add-on to the slurry collection basin, which can carbonate the slurry on a continuous basis. It is connected to the same CO2 silo and evaporator, which supplies the CO2 also for the concrete aggregate carbonation plant.

The installation and implementation of the prototype at the Kästli plant indicates that Neustark’s technology is replicable and can be integrated into existing infrastructures without interfering with current operations. As part of DemoUpCARMA, the new plant fixing CO2 in recycled concrete aggregate and concrete slurry is currently being operated at Kästli for the course of one year. The project goal is to store over 500 tons of CO2 within that timeframe.

Figure 2 - The silo and outside view of the installation at Kästli.

The value chain: sourcing biogenic CO2 from nearby facilities

Neustark sources its CO2 for this project from the nearby wastewater plant Ara Region Bern. The biogenic CO2 produced by the plant – which Ara Region Bern was releasing into the atmosphere before this collaboration – is captured from a point source and liquefied for transportation. Afterwards, a biogas-fueled truck brings the CO2 to the storage plant using dedicated vessels of 20 tons of liquid CO2.

Figure 3 – Preparing the captured and liquified CO2 from Ara Region Bern for transportation to the storage plant.

The impact: removing CO2 from the atmosphere – but also reducing CO2 in concrete production

The collected data is afterwards fed into the life cycle assessment model of the Paul Scherrer Institut (PSI). In combination with the surrounding value chain, the environmental benefits and potential adverse side effects of the new technology and mix designs can be quantified.

Also, as part of the project, Empa is investigating the effect of the carbonation process on the properties of ready-mix concrete. The collected know-how will help to develop clever mix designs, which may result in a reduced cement content in concrete. This would subsequently reduce the overall CO2 footprint of newly produced concrete.

The technology and process that are being developed and tested within the DemoUpCARMA project allow us to not only help to remove CO2 from the atmosphere and store it permanently in concrete, but also help to reduce the CO2 footprint of the building industry.

Author

Johannes Tiefenthaler is Neustark's co-founder and co-CEO. He holds a PhD from ETH Zurich, where he developed CO2 mineralization technologies.

References

Tiefenthaler J, Braune L, Bauer C, Sacchi R, Mazzotti M; Technological Demonstration and Life Cycle Assessment of a Negative Emission Value Chain in the Swiss Concrete Sector; Frontiers in Climate (2021); DOI: https://doi.org/10.3389/fclim.2021.729259