#2 Blog

Investigating concrete mix design with carbonated RCA

June 2023 - Andreas Leemann, Frank Winnefeld, Johannes Tiefenthaler

The previous blog post "How we can lower the carbon footprint of concrete today" gives an insight into the carbonation process of recycled concrete in order to remove CO2 from the atmosphere and generate negative emissions. In this new blog post, we’d like to highlight the microstructural changes occurring in recycled concrete aggregates (RCA) as a result of accelerated carbonation. These changes have significant implications for concrete production. Laboratory analyses not only show an increased compressive strength but also the potential to reduce the cement content in recycling concrete – which offers in terms of lowering the carbon footprint. Understanding these microstructural transformations becomes paramount in paving the way for the commercialization of carbonated concrete.

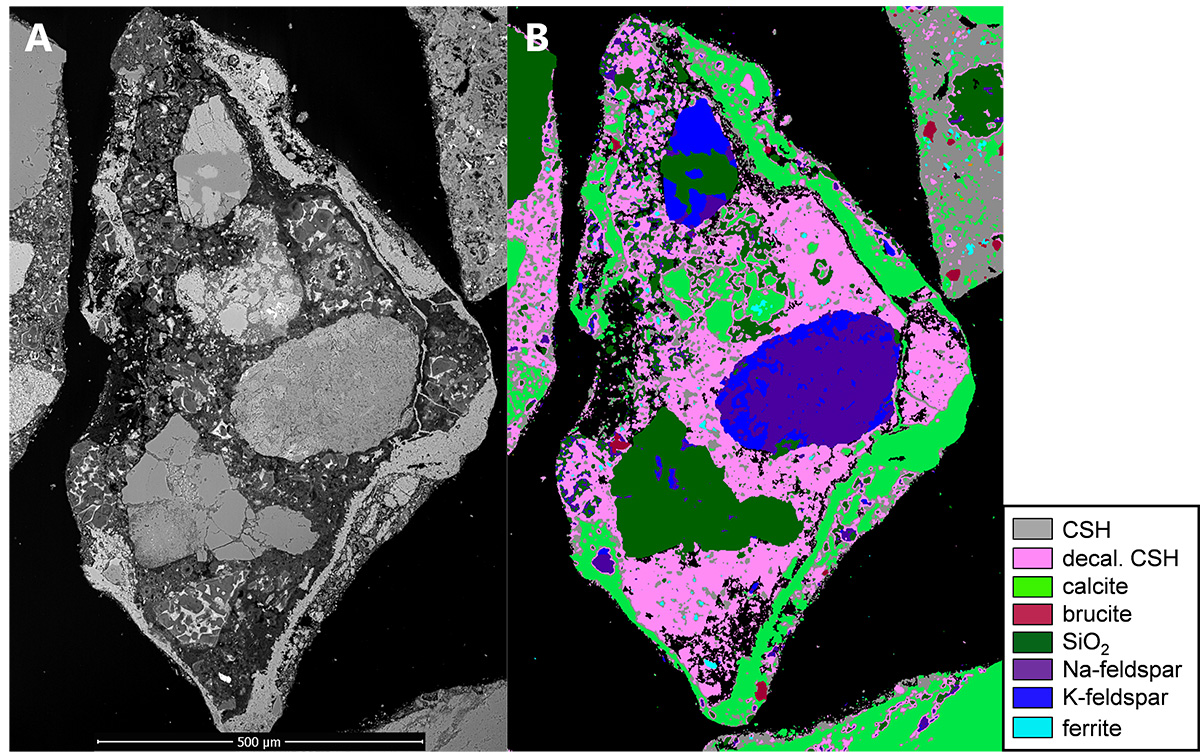

The microstructural investigation starts with scanning electron microscopy. It reveals that RCA particles exposed to accelerated carbonation with 100 % CO2 show patches at their surface where the original cement paste, the “glue” that keeps the grains together, has been altered. These patches consist of a dark matrix and bright layers and clusters. Small particles can be completely altered (Figure 1A). Such patches are absent in non-carbonated RCA.

Chemical analysis with energy-dispersive X-ray spectroscopy reveals that the dark phases consist mainly of decalcified calcium-silicate-hydrate (C-S-H) the main product of cement hydration giving concrete its strength. Additionally, small amounts of silica gel containing aluminum, magnesium and potassium are present as minor component. The bright layers and clusters consist of calcite (CaCO3).

Enhanced physical properties

Phase clustering based chemical analysis [1] makes these two major products of accelerated carbonation – the decalcified C-S-H (pink) and the calcite (green) - easily recognizable (Figure 1B). Amorphous silica-rich phases like the decalcified C-S-H have proven to react when they are exposed to newly formed cement hydrates like portlandite (Ca(OH)2) in the recycling concrete [2]. This reaction leads to the formation of additional C-S-H with a regained higher calcium content increasing the compressive strength of the new recycling concrete [3].

Figure 1: Small RCA particle completely altered by the exposure to 100 % CO2 showing a dense, light grey calcite layer and dark grey, decalcified C-S-H (A). These two phases are highlighted in light green (calcite) and pink (decalcified C-S-H) based on chemical analysis with subsequent phase clustering (B).

In the next step carbonated RCA representing 60 mass-% of the total aggregate content was used for the production of types A and C concrete which are the most commonly used mixtures in the building industry in Switzerland. These standardized types differ by their cement content and water-to-cement-ratio. The resulting properties in the fresh and the hardened state were compared to a reference recycling concrete produced with uncarbonated RCA.

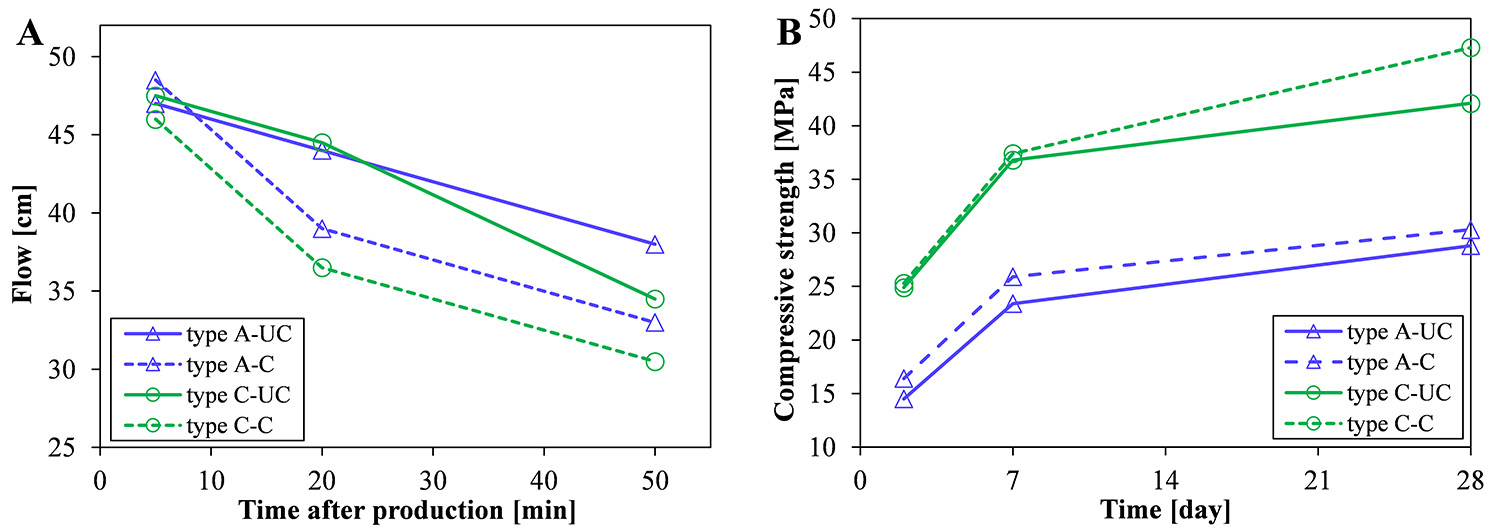

Five minutes after their production all recycling concrete mixtures show nearly the same fluidity expressed as flow (Figure 2A). As it is typical for concrete, flow decreases with time due to the ongoing cement hydration, i.e. the hardening process. Surprisingly, both recycling concrete mixtures containing carbonated RCA exhibit a faster decrease then the ones with uncarbonated RCA. Additionally, both recycling concrete mixtures containing the carbonated RCA achieve a higher compressive strength in the hardened state than their counterparts produced with uncarbonated RCA (Figure 2B).

Figure 2: Recycling concrete of types A and C show a faster decrease of flow in the fresh state when carbonated RCA (C-C) are used instead of uncarbonated ones (C-UC) (A). The use of carbonated RCA leads to a higher compressive strength in the hardened state compared to the uncarbonated ones for both types of recycling concrete (B).

The observed faster decrease of flow of the recycling concrete with carbonated RCA is likely linked to the presence of the decalcified C-S-H. This faster decrease can easily be counteracted by adding a special admixture during concrete production retarding cement hydration. This is necessary, because the concrete has to keep a certain fluidity during its transport from the concrete plant to the construction site. The increase in compressive strength of the recycling concrete with carbonated RCA is caused by the participation of the decalcified C-S-H in cement hydration leading to the formation of additional C-S-H.

Decreasing cement content in recycling concrete

This strength increase offers the potential to decrease the cement content in recycling concrete. As such, the advantages of carbonating RCA are twofold. First, RCA are able to absorb CO2 and remove it from the atmosphere. Secondly, the potential to reduce cement content in recycling concrete containing carbonated RCA may lead to lower CO2 emission attributed to its production. The result obtained in the project indicate that about 10 % of the total CO2 emission linked to the production of cement clinker originally present in the RCA can be absorbed by carbonation. The cement content in recycling concrete produced with carbonated RCA can be potentially reduced by 5-7 % decreasing the CO2 footprint of recycling concrete. Thus, the use of carbonated RCA in recycling concrete can lead to an overall reduction of the geogenic CO2 emission of approximately 15 %, if the CO2 captured by the carbonation of the RCA and the reduction of the cement content are considered.

References

[1] Münch, B., Martin, L.H. and Leemann, A., 2015. Segmentation of elemental EDS maps by means of multiple clustering combined with phase identification. Journal of microscopy, 260(3), pp.411-426.

[2] Lothenbach, B., Scrivener, K. and Hooton, R.D., 2011. Supplementary cementitious materials. Cement and Concrete Research, 41(12), pp.1244-1256.

[3] Zajac, M., Skocek, J., Durdzinski, P., Bullerjahn, F., Skibsted, J. and Haha, M.B., 2020. Effect of carbonated cement paste on composite cement hydration and performance. Cement and concrete research, 134, p.106090.

More info

More info on CO2 storage in concrete can be found in the interim report and soon in the final report that will be published at the end of the year.